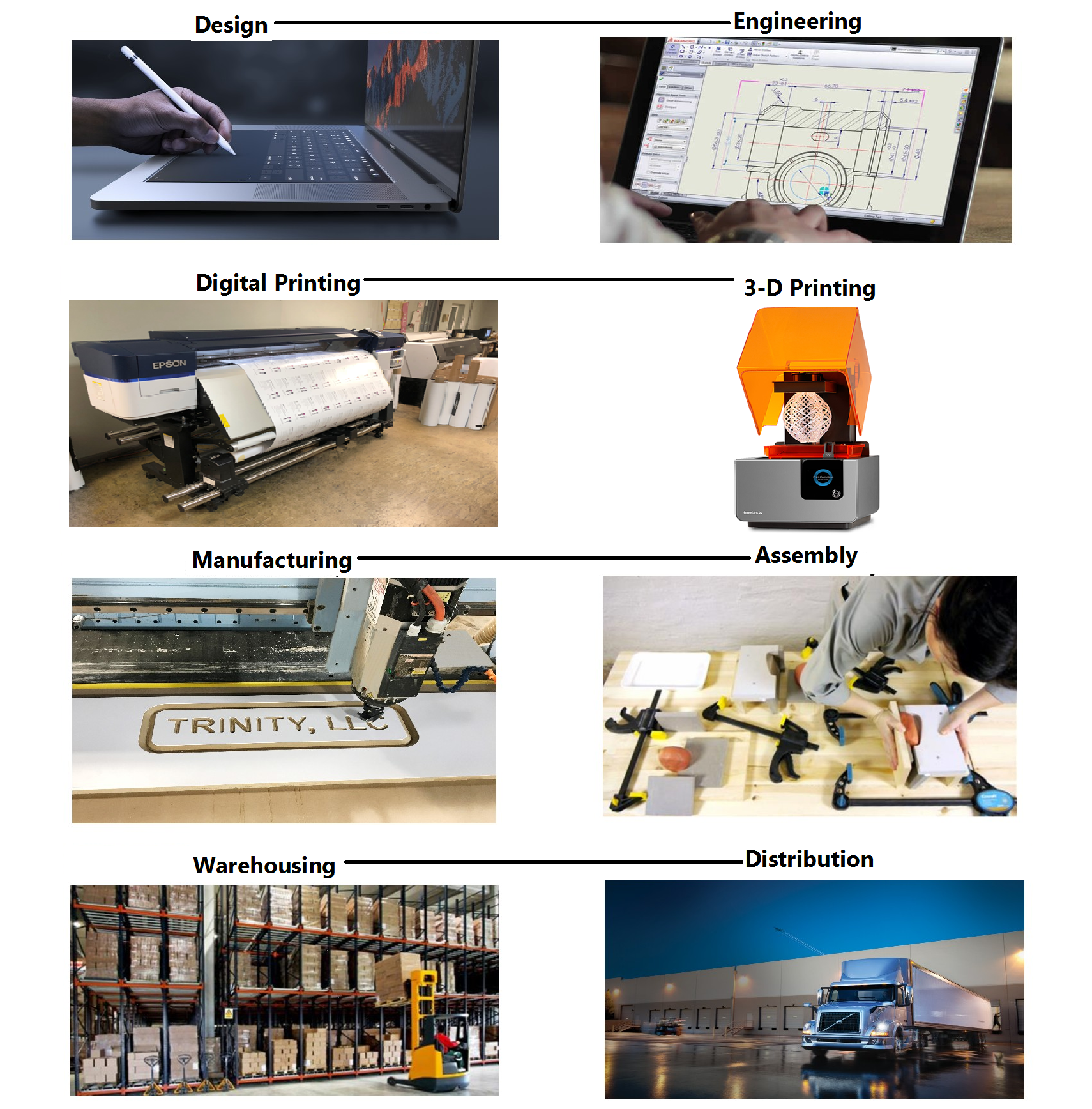

TRINITY is a “Total Solutions Company”. We combine design, electrical-mechanical engineering, manufacturing, assembly, and fulfillment, virtually all under one roof in our 125,000 square foot NJ facility. This is augmented with a global raw material resources network, allowing Trinity to produce high quality fixtures at highly competitive price points.

Further, through excellent process and a strong enterprise system, our totally integrated facility operates in real-time allowing fast, accurate, and detailed accounting of each project as it is happening. This translates to a faster speed to market, and happy clients.

Manufacturing disciplines covered include:

- Custom LED Lighting–designed, engineered, and produced by Trinity.

- Plastic thermoforming and injection molding.

- Plastic fabrication, including Styrenics, Acrylics, and many other forms of sheet goods (laser and CNC machining, bending, gluing, edge finishing).

- Wood manufacturing from basic melamine to high pressure laminated surfaces, pre and post laminated.

- Metal including wire, sheet, and tubular construction.

- Full assembly operation with automation-capable equipment.

- Digital and multi-color screen printing presses with automated inline UV drying equipment.

- Custom painting.

- Digital Printing.

- 3D printing.

- Full service model shop with expert model makers.

- 20 dock doors to handle fulfillment, shipping and receiving.

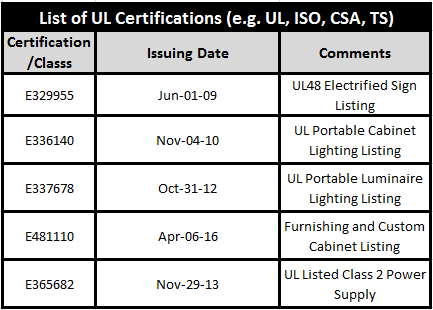

Certifications & QR Coding

- UL Certifications: TRINITY is a UL-Listed facility. We have a number certifications the can be used for new and existing clients. This greatly reduces speed to market and in most cases, eliminates high costs related to client specific fixtures requiring a UL Listing.

- Date Stamping: Client displays are date-stamped for any needed in-field follow-up.

- QR Codes: Displays and lighting systems that require in-field information are labeled with a QR Code that can be accessed in-store by install companies or retailers via a PC, Tablet, or Smartphone.